Kanex recommends Indirect High-Pressure (IHP) CO2 for EDM and CNC machine.

All major components of the system comply with international standard and are highly reliable to protect the equipment in case of early fire.

The UL listed thermo sensitive tube is the lifeline of the whole system and act as the responder for any fire/temperature rise in the enclosure.

The Detection Tubing is routed around the base of the ram just above the typical operating oil level, providing 360 degrees of fire detection and suppression. The tube runs through intricate spaces inside the machines.

The detection tubing can also be run to the front the machine when an optional manual release is required.

Large nozzles are installed well above the oil surface on both sides of the ram deliver a high volume of CO2 to extinguish the fire. The CO2 is delivered as a gentle mist to keep the burning oil from splashing, which would spread rather than suppress the fire.

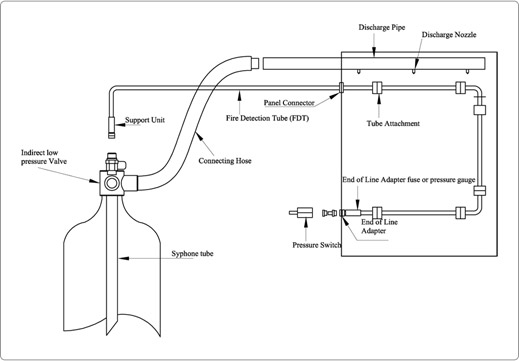

The Indirect system utilizes Heat Sensing Tube as fire sensing ONLY. Suppression of fire is delivered via copper, SS or Braided pipe.

The nearest surface of Heat Sensing Tube bursts due to heating it actuates the valve & agent discharges through strategically placed nozzles within protected enclosure.

| MODEL | Specifications | MODEL | Specifications |

|---|---|---|---|

| Extinguishing Agent | CO2-IHP | Capacity | 4.5, 6.5, 9, 22.5, 45 kg |

| Working Pressure | 60-70 bar | Cylinder Approvals | CCOE |

| Gas Approvals | IS: 15222 | Other Applications | Transformers, DG sets, Fume hoods e.t.c., |