All major components of the system comply with international standard and are highly reliable to protect the equipment in case of early fire.

The UL listed thermo sensitive tube is the lifeline of the whole system and act as the responder for any fire/temperature rise in the enclosure.

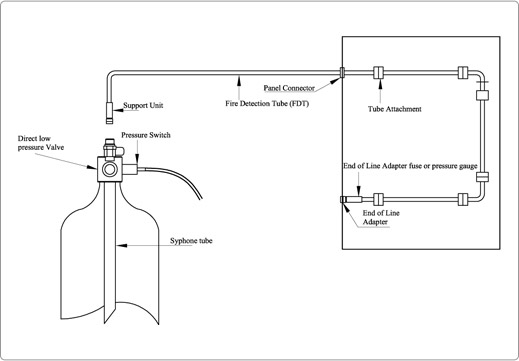

The Detection Tubing is routed around the critical components in the panel providing 360 degrees of fire detection and suppression. The detection tubing can also be run to intricate and difficult places.

When a fire break out, the point on the pressurized FDT nearest the heat source will burst, allowing the fire suppression agent to flow from the extinguishing agent cylinder through the tubing, and out of the rupture hole which forms nozzle and extinguishes directly at the source of the fire. The result is a long discharge of agent in the immediate vicinity of the fire, suppressing the fire where it starts.

The direct system utilizes Heat Sensing Tube as both fire sensing & suppression of fire by delivering the agent.

The nearest surface of Heat Sensing Tube bursts due to heating & it forms effective discharge nozzle.

Due to which pressure drops in Heat Sensing Tube & entire content of cylinder discharges.

| MODEL | Specifications | MODEL | Specifications |

|---|---|---|---|

| Extinguishing Agent | CO2-DHP | SYSTEM'S WORKAvailable Capacities | 4.5, 6.5 kg capacity subject to design calculation |

| Working Pressure* | 60-70 bar | Cylinder Approvals | CCOE |

| Gas Approvals | IS: 15222 | Other Applications | Transformers, DG sets, Fume hoods e.t.c., |