Kanex recommends Indirect Low Pressure Systems for wind turbines.

All major components of the system comply with international standard and are highly reliable to protect the equipment in case of early fire.

The UL listed thermo sensitive tube is the lifeline of the whole system and act as the responder for any fire/temperature rise in the enclosure.

The red detection tubing is routed throughout the alternator which improves reaction time and reduces the potential for machine damage.

Large nozzles deliver a high volume of clean agent gas to quickly suppress the fire in its initial stage.

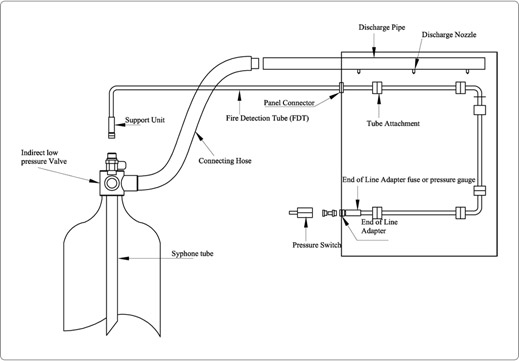

The Indirect system utilizes Heat Sensing Tube as fire sensing ONLY. Suppression of fire is delivered via copper, SS or Braided pipe.

The nearest surface of Heat Sensing Tube bursts due to heating it actuates the valve & agent discharges through strategically placed nozzles within protected enclosure.

| MODEL | Specifications | MODEL | Specifications |

|---|---|---|---|

| Extinguishing Agent | FE 36/HFC236fa FK-5-1-12 FM 200/HFC227ea |

Capacity | 2, 4, 6 kg |

| Working Pressure | 13.5-15 bar | Cylinder Approvals | CE |

| Gas Approvals | UL/FM/EPA SNAP |