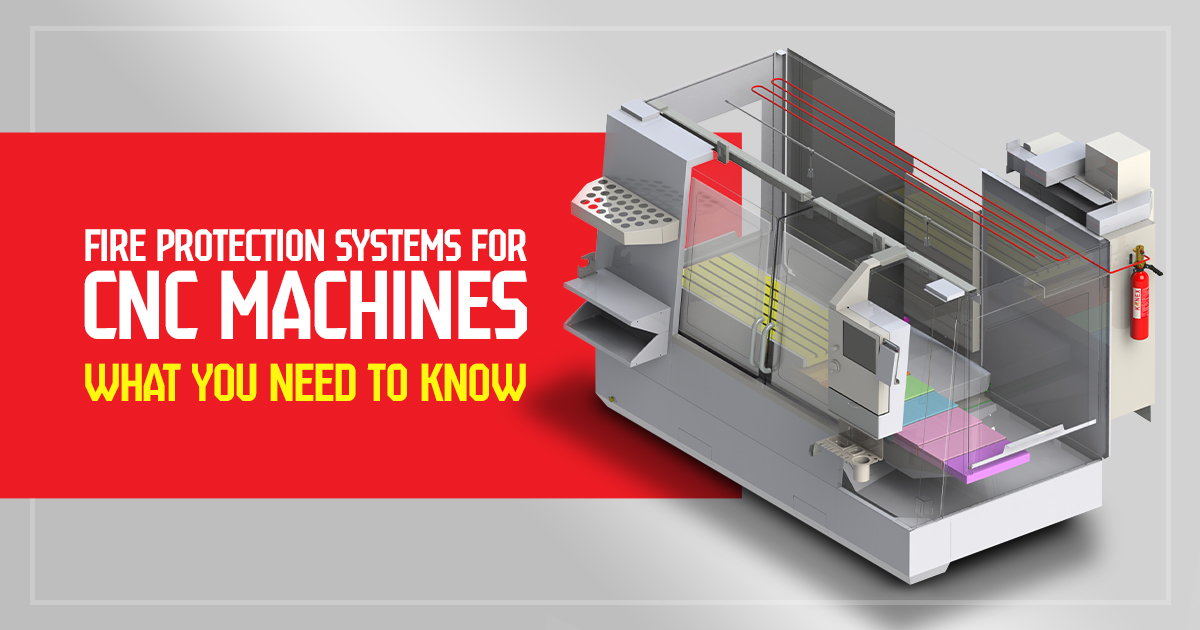

Fire Protection Systems for CNC Machines: What You Need to Know

- July 30, 2025

For a long time, the manufacturing line has been dependent on the CNC machines. These machines, for example, use pre-programmed software to control tools and equipment. If it’s milling, cutting, or shaping, CNC machines like lathes, routers, plasma cutters, and laser cutters are the backbone of modern production floors.

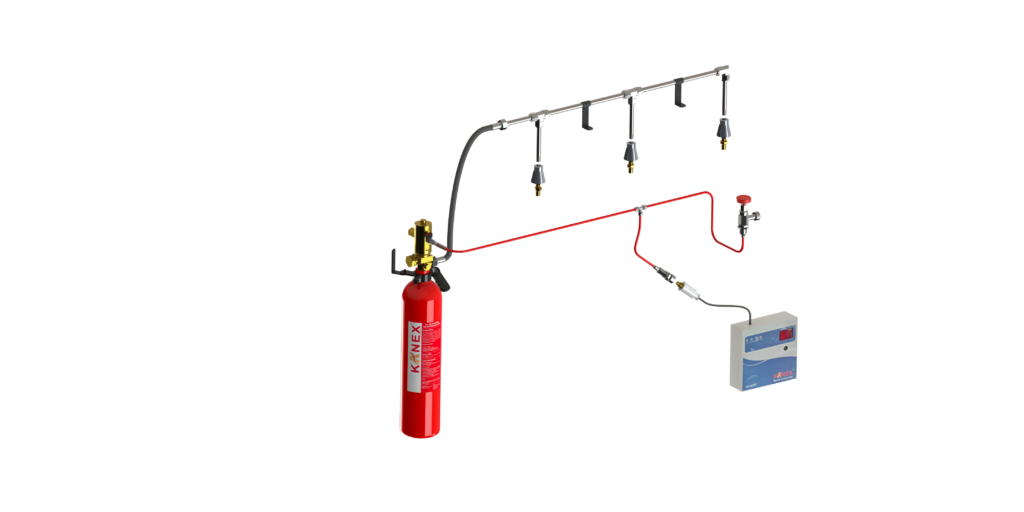

These systems are built to catch and kill fires inside machines like CNCs before they get worse. One of the best ways to do that is by installing a system that’s made for these machines, like Kanex Fire Solutions Limited’s IHP CO2 system.

Why CNC Machines Can Catch Fire

CNC machines mostly work with oils, cutting fluids, and high-speed tools that heat up during operation. And this can create a fire risk. Something like a jammed tool, sparks from metal, or even an electrical short can start a fire inside the cabinet. And the fires that happen inside closed CNC units spread very fast.

What Is an IHP CO₂ Fire Suppression System?

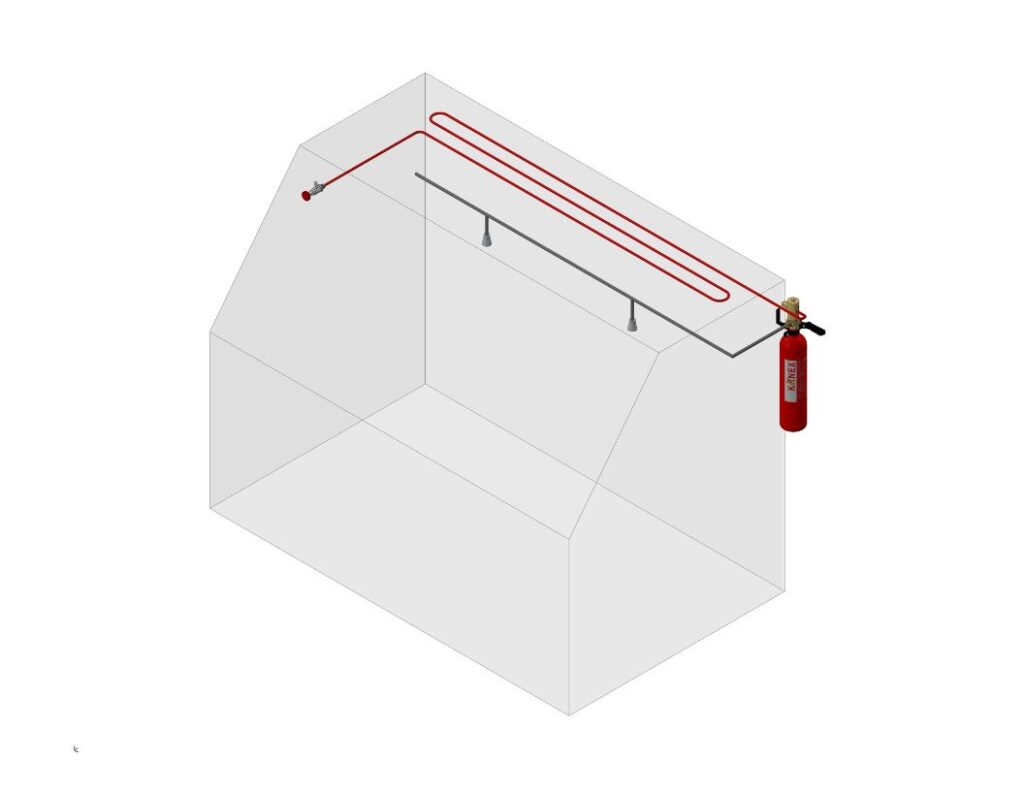

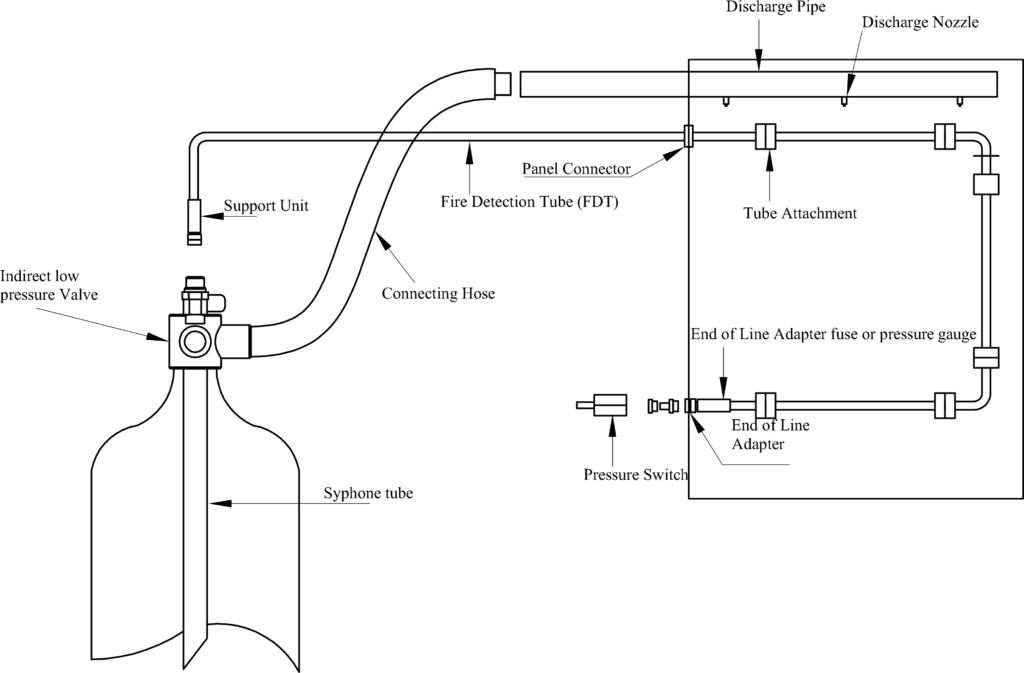

An IHP system means Indirect High Pressure. It’s a type of fire suppression system that uses CO2 gas to put out fires. It works with a fire detection tube system placed inside the machine, right near the parts that heat up the most. If the tube senses a high temperature or a fire, it bursts. That break triggers the release of CO2 from a cylinder, which then floods the space through a separate nozzle.

It doesn’t spray out from the tube itself. But the system is smart enough to release the gas from a different line for better coverage. The fire is put out fast, and the machine doesn’t get soaked or damaged in the process.

How the Kanex KATS IHP System Works in CNC Machines

Kanex Fire Solutions Limited offers a system made exactly for CNC machines. The tube goes inside the cabinet, close to cutting areas or places where fires usually start. When it detects heat, it bursts, and the indirect high-pressure CO2 system releases gas to that spot.

And you may be surprised to know that it works without needing power. Even if the machine is running overnight and no one is around, it’ll still activate and stop the fire before it spreads.

Key Features of the Kanex IHP CNC System

- Automatic fire detection and release

- No electrical supply required

- Doesn’t leave residue or water

- Stays fully inside the machine enclosure

- Works in enclosed and unmanned environments

- Safe for electronics and sensitive parts

Why Go With Kanex Fire’s CNC IHP System?

Kanex Fire Solutions Limited has built this system keeping CNC machine safety in mind. It’s easy to install, works without power, and doesn’t require any changes to your machine. More than anything, it reacts fast. And stops the fire before it spreads and saves both equipment and downtime.

Conclusion

Fire may not happen every day, but if it does inside a CNC machine, it can cause big losses. A good fire suppression system, like Kanex IHP CO₂ for a CNC machine, can stop the fire quickly without damaging the machine or work. Just call or message us if you need more information about this product.